Black soldier flies – Environmentally conscious insects

Do you believe the Swiss are effective recyclers? You may want to reconsider after learning about black soldier flies. Native to the Americas, these insects are efficiently upcycling biowaste, transforming it into valuable products that can be used as livestock feed.

A black soldier fly larva on Daniela’s finger. Image: © Kaan Mika

On desktop: Hold down the Shift key and scroll to zoom in or out of the image. Hold down the left mouse button to rotate.

On mobile: Pinch zoom with two fingers. Use two fingers to pan. Rotate with one finger.

Classification

- Kingdom

- Animalia

- Phylum

- Arthropoda

- Class

- Insecta

- Order

- Diptera

- Family

- Stratiomyidae

- Genus

- Hermetia

- Species

- H. illucens

Biowaste management

Due to urbanization and rapid economic developments, the waste produced is exponentially increasing, predicted to reach 3.4 billion tons per year by 2050. In low- and middle-income countries, around 60% of this waste is organic or called biowaste. This accumulating biowaste significantly contributes to pollution and greenhouse gas emissions around the world, as well as the rapid consumption of natural resources. Most of the biowaste produced is from agriculture and household waste.

In low and middle-income countries, most of the way is biowastes are either burnt or openly dumped/landfilled, both solutions not being environmentally friendly and having health consequences for local communities. Did you know that some insect species can help us with this environmental task? One such insect that has gained increased attention over the last several decades is the black soldier fly, specifically its larvae.

Daniela is holding a tray full of black soldier fly larvae. Image: © Kaan Mika

The black soldier fly larvae (BSFL) (Hermetia illucens L.) are increasingly being used to address the challenges of biowaste management. These insects thrive on a wide range of biowaste, including food scraps, animal and human waste, and brewery byproducts. Once fully grown, the nutrient-rich larvae can be harvested and used as high-protein, high-fat feed for poultry, pigs and fish. While chickens benefit from this sustainable food source, BSFL simultaneously break down large amounts of waste that would otherwise contribute to pollution. Other advantages of BSFL include their low water consumption, minimal greenhouse gas emissions, and they require limited land to grow. In addition to recycling nutrients for protein and fat production in a more environmentally friendly way, BSFL also produces a compost-like residue that supports plant growth and improves soil quality (read more in this article).

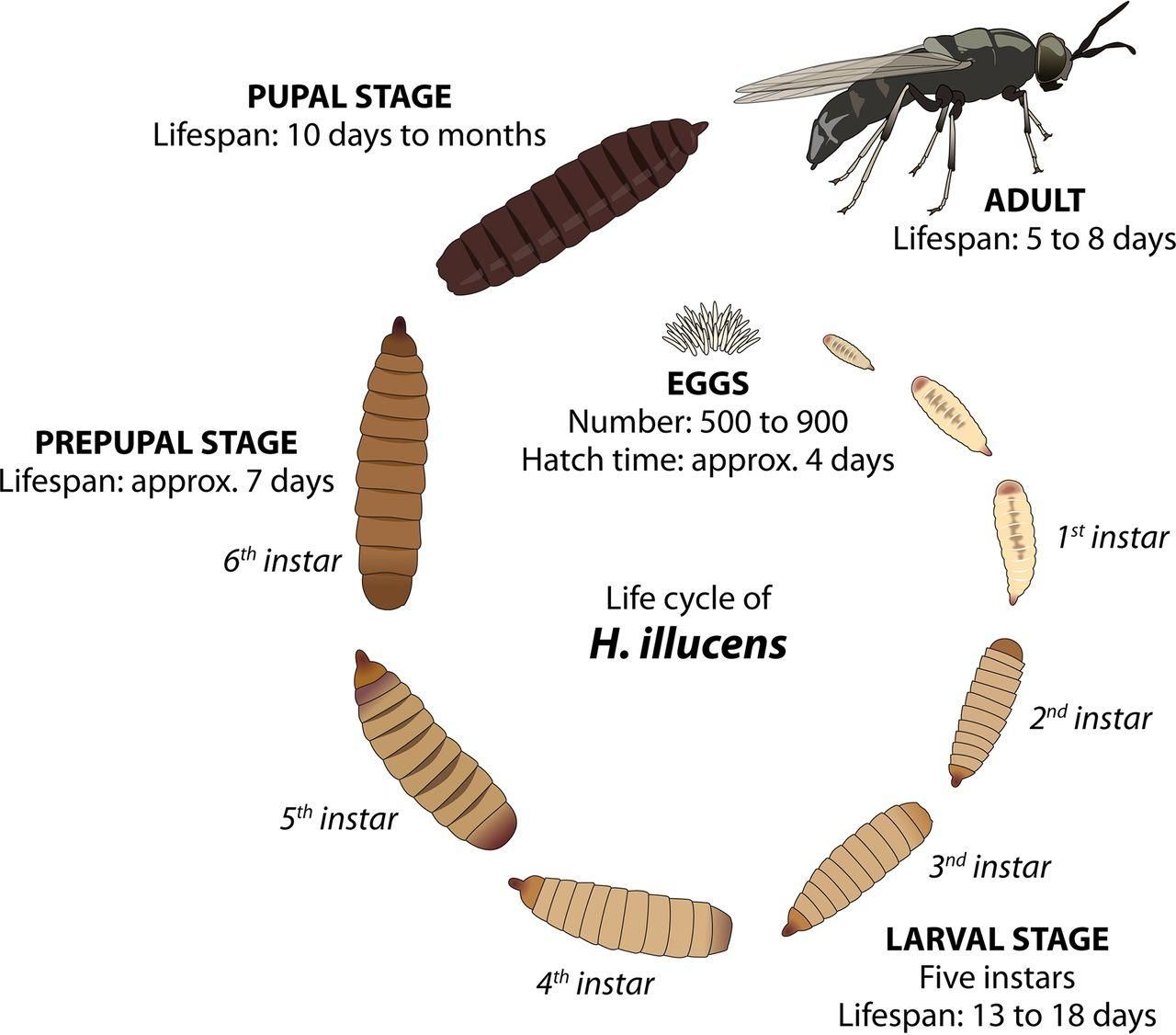

The life cycle of the black soldier fly. Image: De Smet J et al. 2018).

Black soldier flies hatch from their eggs and undergo six larval stages, taking approximately 2–3 weeks to reach the prepupal stage and another week to reach the pupal stage. At the pupal stage, they stop moving and continue their development until they eventually transition into adulthood, emerging as flies. This final stage is much shorter than the others, with the primary purpose being to mate and reproduce. After mating, the female fly deposits 500–900 eggs in dry cracks near decaying organic material, which serves as food for the newly hatched larvae. The eggs hatch within four days, and the larvae begin feeding on the surrounding material, continuing the cycle.

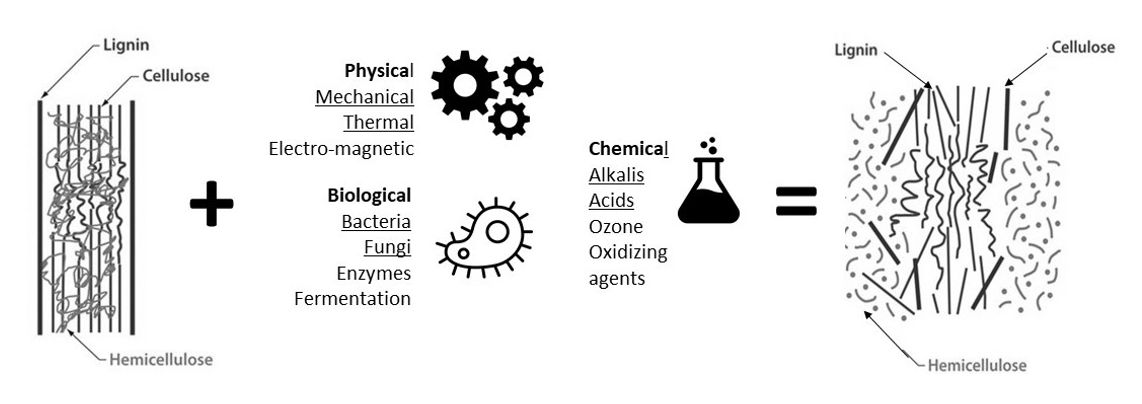

However, two important questions remain. First, most biowaste contains high levels of plant fibers (cellulose, hemicellulose, and lignin), which make the environment unsuitable even for BSFL. These molecules are difficult for the larvae to break down, significantly impacting their performance. Second, what about the safety of the end product? Large-scale insect rearing could lead to pathogen accumulation within the population. To mitigate this, safety measures must be implemented, and the end product should have a long shelf life to effectively replace soybean and fish-based feed.

Daniela in front of the black soldier fly rearing facilities at Eawag, Dübendorf, Switzerland. Image: © Kaan Mika

Dr. Daniela Peguero studied BSFL in the lab of the Sustainable Food Processing Group at ETH Zurich, Switzerland, in collaboration with Sandec/Eawag. Her doctoral thesis examined biowaste pre-processing and the post-processing of insect products to enhance the viability and safety of insect-based systems.

Pre-processing

To optimize the energy and time required for the bioconversion of lignocellulosic (cellulose-, hemicellulose-, and lignin-rich) biowaste, pre-processing techniques can be employed to enhance the material's suitability for larval growth. In her thesis, Daniela evaluated three such methods:

1. Physical (mechanical and thermal) treatment

Grinding the biowaste into smaller fragments makes it easier for the larvae to consume. Heating may help to release more beneficial nutrients, though too much heat can kill helpful microbes.

The study found that grinding brewery spent grain and grass clippings was more effective than heat treatment. Larvae that fed on ground waste grew 13–32% more than those on untreated waste, demonstrating that mechanical treatment boosts larval growth.

2. Chemical (alkaline) treatment

Soaking the waste in ammonia for three days helps break down the fibers and makes nutrients easier to absorb.

While the fibers were broken down effectively, the ammonia appeared to be harmful to the larvae. Ammonia pretreatment was tested on cow manure, grass clippings and brewery spent grain. On all wastes tested, larval growth was negatively affected, suggesting that ammonia might be toxic. This means that other types of chemicals need to be tested to find a better alternative – one that effectively breaks down fibers while also supporting larval growth.

3. Biological (bacteria and fungi) treatment

This method uses fungi or bacteria to break down plant fibers over time, but the process is slow and harder to control.

Fermenting agri-food byproducts for up to a week with a starter culture can also enhance larval growth. Fungal pretreatments should be further explored to determine whether they can improve the breakdown of fiber-rich wastes, like fruit scraps.

The best treatment depends on the type of waste, the available time, and the goal of the process. In Daniela’s study, mechanical grinding proved to be the most effective approach for boosting larval growth.

Schematic on how plant fibers (cellulose, hemicellulose and lignin) are broken down by different physical, chemical and biological methods to then make it easier for the larvae to eat. Image: adapted from Mosier N et al. 2005 and Peguero et al., 2022.

Low-energy electron beam (LEEB) and food safety

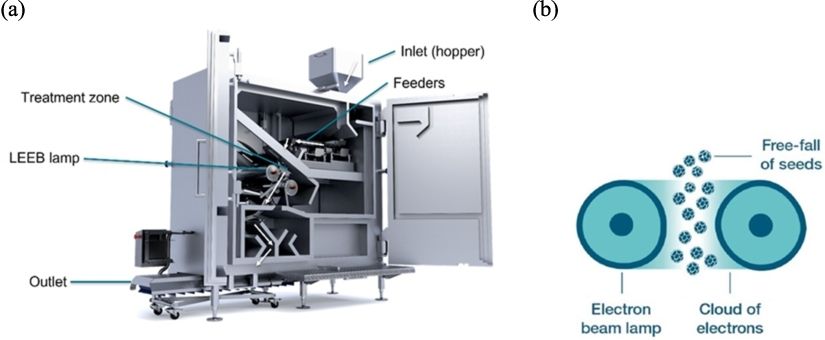

BSFL are being considered as an alternative protein source for poultry, pigs, fish or even humans due to their high nutritional value and lower environmental impact. However, they can carry harmful microbes that may cause foodborne illnesses if not properly processed. Traditional methods like boiling and drying can reduce microbes but may not fully eliminate resistant bacteria, while also affecting the nutritional quality. A newer method, low-energy electron beam (LEEB) treatment, was explored as a means to kill bacteria on dried products without reducing the product’s quality. LEEB uses a controlled stream of electrons to kill bacteria without the need for heat or chemicals. This study investigated whether LEEB can effectively make insect-based foods safer and extend their shelf life for industrial use.

This large industrial LEEB (Low-Energy Electron Beam) unit uses two electron beam lamps to treat food or feed products with electrons as they move through the system – from the feeder to the outlet – enhancing their safety. Image: Peguero DA et al. 2023; source: Bühler AG, Uzwil, Switzerland.

The LEEB treatment helped reduce harmful microbes in BSF potentially extending shelf life. Although there was a small increase in fat breakdown (lipid oxidation), the levels were still low and acceptable for use in animal feed. This suggests that LEEB could be a useful extra step after gentle heating to improve safety without damaging the product. More research is needed, especially on insects with higher levels of microbes and on the long-term freshness of microwave-dried insects.

Concluding remarks

There are many different pretreatments that can be explored to improve BSFL farming. Daniela’s study focused on three common types of waste: cow manure, brewery spent grain, and grass clipping, but BSFL can be fed many other materials. Future research should continue testing new pretreatments, including using fungi to help break down waste, and experiment with a wider variety of waste types to better understand what works best.

Finally, microbiological safety is another key area. While LEEB was effective in reducing harmful microbes, it may not be affordable or available everywhere. That’s why it is important to explore lower-cost alternatives that can still help make the process safe. Some pretreatment methods, like fermentation, are used to break down tough plant fibers, but they may also help reduce harmful bacteria and pathogens in the waste before it is fed to the larvae. Future research should investigate whether these methods can also improve the microbial safety of the larvae themselves. This is especially important in countries where live larvae are directly fed to animals like poultry, pigs, or fish, without being cooked or dried first.

Overall, by testing new pretreatments and improving safety, we can make BSFL farming more reliable, efficient, and suitable for producing feed on a larger scale.

References

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y. Y., Holtzapple, M., et al. (2005). Features of promising technologies for pretreatment of lignocellulosic biomass.Bioresour. Technol. 96, 673–686. doi: 10.1016/j.biortech.2004.06.025

Palma, L., Fernandez-Bayo, J., Niemeier, D. et al. Managing high fiber food waste for the cultivation of black soldier fly larvae. npj Sci Food 3, 15 (2019). https://doi.org/10.1038/s41538-019-0047-7

Xiang FM. 2024. Black soldier fly larvae recruit functional microbiota into the intestines and residues to promote lignocellulosic degradation in domestic biodegradable waste. Environmental Pollution 340;1:122676. https://doi.org/10.1016/j.envpol.2023.122676

Peguero DA 2023. Pretreatments to improve black soldier fly larvae performance on fibrous biowastes and safeguarding insect-based food and feed. Doctoral thesis. https://www.research-collection.ethz.ch/bitstream/handle/20.500.11850/642205/Doctoral_Thesis_Daniela_A._Peguero_final.pdf?sequence=5&isAllowed=y

Peguero DA, Gold M, Vandeweyer D, Zurbrügg C and Mathys A (2022) A Review of Pretreatment Methods to Improve Agri-Food Waste Bioconversion by Black Soldier Fly Larvae. Front. Sustain. Food Syst. 5:745894. doi: 10.3389/fsufs.2021.745894

Peguero DA et al. 2023. Low energy electron beam to support safe whole dried insect products. Journal of Insects as Food and Feed 10;3:473-489. https://doi.org/10.3929/ethz-b-000631562